What’s Inside our Cutting Boards

When deciding on what aspects should make up our cutting boards, we take in to account many different things. These attributes include the hardness of the wood, the grain, the color, and many other factors to ensure the board last long and is beautiful. In this blog post we are going to be talking all about what’s inside our cutting boards!

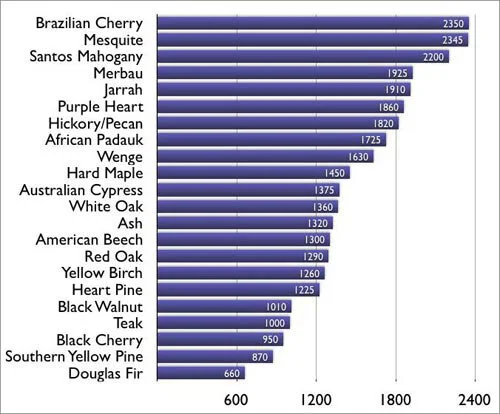

Janka Hardness scale

The first attribute we look at when deciding what type of wood we should use is its hardness. All wood is recorded on a scale called the Janka hardness. We want to make sure the wood we use is predominantly between the range of 900-1500 rating. This is optimal for cutting boards. If the wood is lower then this number, it can cause the knife to easily leave marks on the board, allowing bacteria and other particles to seep through, destroying the longevity of the board. If the rating is higher than 1500, it can cause kitchen knives to dull out faster cutting against this type of wood. However, here at Schnellerco, we have used high rated timber over 1500, for example, purple-heart.

The second attribute we look at is the wood grain. This process takes two applications; first, we examine the wood grain to determine whether it would look and flow well with the other grains picked out for the product. This step is simply for aesthetic purposes. More importantly, we want to choose woods that have a close-grained pattern or non porous. Why a closed-grain pattern? The closed grained blocks water and other bacteria that absorb into the board. If the board more porous it absorbs more water, and has greater tendency to warp and bend.

Another factor we always look for is the toxicity of the wood. This one is quite simple as many exotic hardwoods can have toxic effects. If these "toxic woods" were in our cutting boards, there may be a risk of eating some of the small particles from this wood when you cut on it. This is the main factor as to why we do not use anything that is not FDA approved for cutting on.

The last factor we examine is, of course, the color and what the overall cutting board should look like. With this, we can get inspiration from many different sources, like our college game day line, to more simple ones. When I first design a cutting board, I think about the main color I want on the board and then play around with a contrasting color as an accent. I am a big fan of dark wood, so most of my cutting boards feature dark walnut wood.

Now that we have looked at the significant factors in deciding what goes into our cutting boards, let's get a more detailed looked on what are the most common types of wood we use in our cutting boards.

One of the most common woods we use, and my personal favorite, is Walnut. This dark wood is a dense wood that is fine-grained and polishes up very smoothly. There are 21 species in the walnut family. The most common Walnut we use is the American Walnut, which sometimes can have some lighter tints to the wood from sap found in the tree. However, to ensure pure dark vibrant chocolate color, I have used Persian Walnut. Walnut wood has been used as accent woods and the primary wood in our cutting boards. Walnut wood is a highly prized timber because of its vibrant chocolate color and tight grain, which makes it one of the more expensive woods I use.

Walnut is the primary wood and maple is the accent.

In contrast to Walnut, another wood we use is Maple. The color of Maple can range from white to an off-white cream color, and from times can have a golden hue to it. There are many different types of Maple; most commonly, we use Hard Maple. If you are looking for something exotic in the Hard Maple family, a wood figure/grain called Birdseye Maple and Curly Maple can be found. These wood types have very interesting grain patterns that make them more desired and more expensive. For Schnellerco, we have only used pure Hard Maple which has been both used as an accent color against Walnut or as the primary wood in a cutting board.

The next couple of woods we use are usually just regarded as an accent woods for my cutting boards. First up is African Mahogany. The color of the wood is going to be a dark reddish-brown making it perfect to contrast with a lovely white maple color. However, this wood is typically softer and more porous and open-grained, then the first two. Which is why it is only used in accents in the cutting boards. Another accent wood we have used is Red oak, this type of wood has a medium brown and light red tint to it. This wood has been used with a dark walnut color; it is a very dense wood. Although, it is very porous, and the grain is open, much like the African Mahogany.

One of the more exotic woods we've used in my cutting boards is Purple-heart, which is a deep eggplant purple. The color does fade over time, but don't worry, the coloring takes quite a while to turn into the dark brown with a purple tint. Purple-heart wood makes a excellent contrast to any wood, and it is prominently featured in our LSU cutting board. Lastly, another exotic wood we use is Yellow Heartwood. (the people who came up with these names sure are creative). This wood has a golden yellow color, and the color only darkens with age. This wood is found in Brazil and is featured in the LSU cutting board. Both of these exotic woods are non toxic and make beautiful contrasting pieces.

Finally, all these different types of woods are a small portion of what is out there. As we grow this business, I wish to continue to add new wood types to our cutting boards like blood wood, cheery, and many more to allow a variety among the products. There is something beautiful in every kind of wood used as they each tell a story, and I hope to continue their story by creating something useful for someone to love and use.